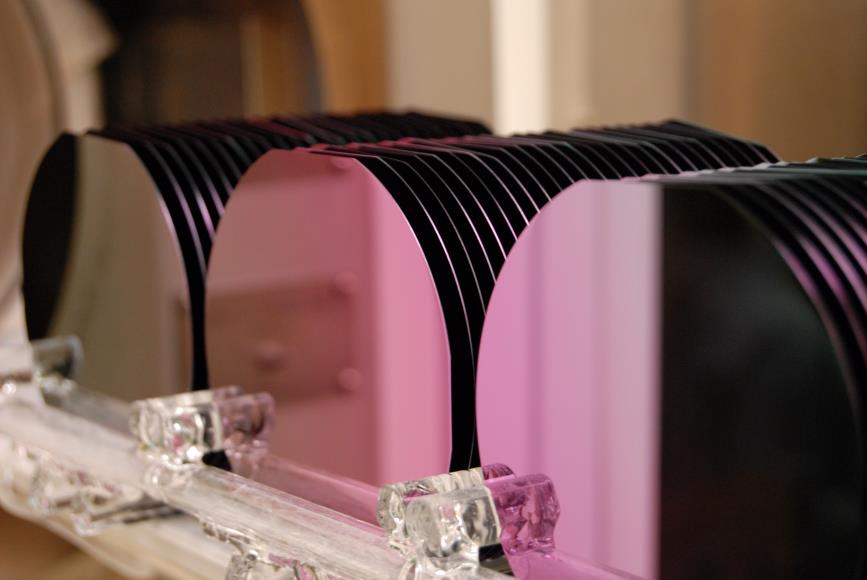

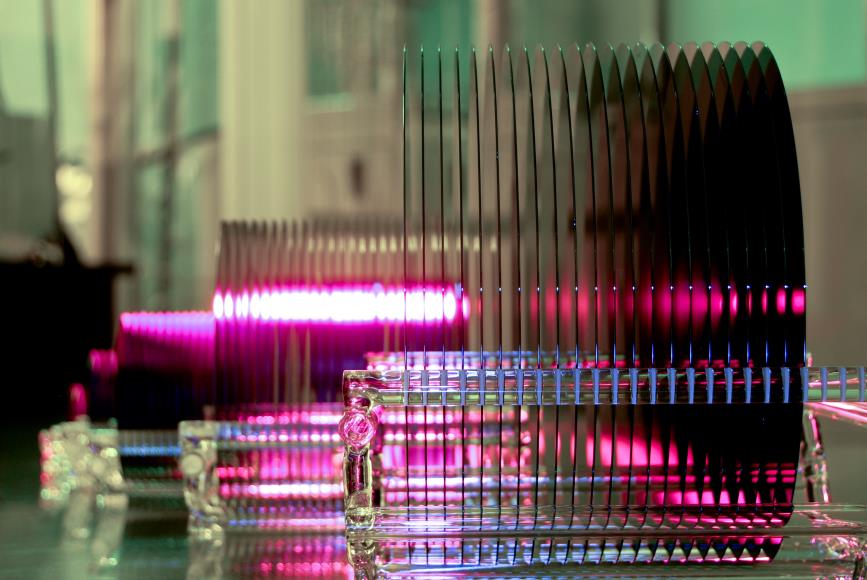

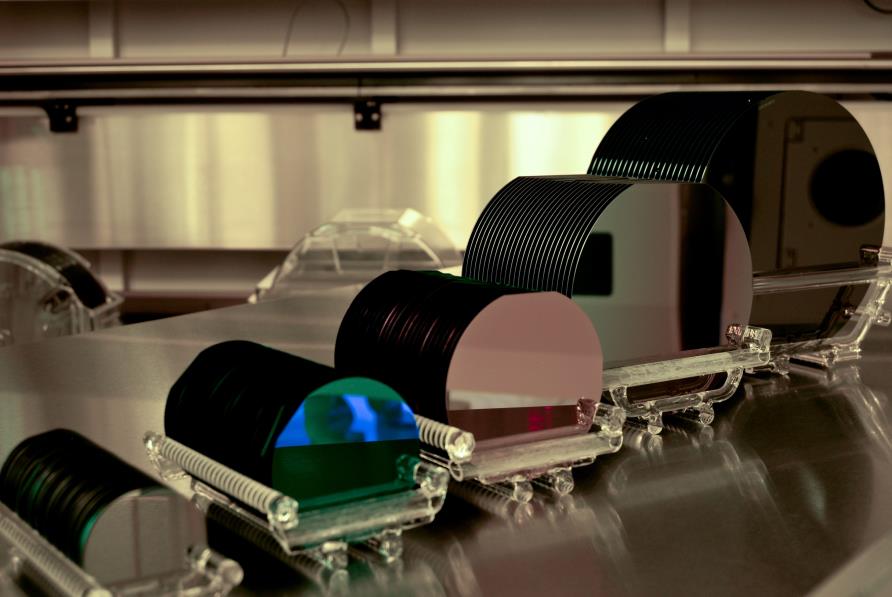

In addition to the wide range of products, Si-Mat also offers special additional or follow-up treatments. Our customers also place their trust in the services we offer. These are carried out by our service partners and manufactured according to your individual specifications. If you have any special requirements, please contact us.

Thin Films and Oxides

We can offer you these types of coatings

Silicon Oxides

The main difference between dry and wet oxide lies in the manufacturing processes and the resulting properties of the oxide layer on the silicon wafer: overall, dry oxidation is preferred for precise and thin oxide layers, while wet oxidation is used for faster and thicker oxide layers that are less dense. The choice between the two methods depends on the specific requirements of the application and the desired properties of the oxide layer.

Wet Oxide

(Si + 2 H2O -> SiO2 + 2 H2)

In wet oxidation, silicon is oxidized in an oxygen-containing environment at high temperature and high humidity (typically above 800°C). Compared to dry oxidation, the oxide layer grows faster and with a lower density during wet oxidation. The resulting oxide layer is less dense and has a higher growth rate. Wet oxidation is often used for thicker insulation oxide and can also be used to produce gate oxides in transistors.

Dry Oxide

(Si + O2-> SiO2)

In dry oxidation, silicon is oxidized in an oxygen-rich environment at a high temperature (typically above 900°C). This process produces a thin and uniform oxide layer on the silicon surface. Dry oxidation is characterized by a slow growth rate and high density, resulting in a uniform and dense oxide layer. This type of oxidation is often used for precise structuring and insulation purposes.

Wet Thermal Oxidation (WTO):

Thickness: 100 – 6000nm

Thickness Tolerance: +/- 5 %

Refractive Index: 1,456 +/- 0,02 @ 632,8 nm

Film Stress: -320 +/- 50 MPa

Temperature: 900 °C – 1050 °C

Gases: Oxygen

Equipment: Horizontal Furnace

Wafer: Standard wafers 2″ to 8“

Sides Processed: Both

Dry Thermal Oxidation (DTO):

Thickness: 10 – 300nm

Thickness Tolerance: > 50nm +/- 5%

Refractive Index: 1,456 +/- 0,02 @ 632,8 nm

Film Stress: -320 +/- 50 MPa

Temperature: 900 °C – 1050 °C

Gases: Oxygen

Equipment: Horizontal Furnace

Wafer: Standard wafers 2″ to 8“

Sides Processed: Both

PECVD Oxide:

Thickness: 30 – 500nm

Thickness Tolerance: > 100nm +/- 7%

Refractive Index: 1,46 +/- 0,02 @ 632,8 nm

Film Stress: -400 +/- 50 MPa

Temperature: 300 °C – 400 °C

Gases: Saline, Nitrous Oxide

Equipment: Plasma-enhanced chemical vapour deposition

Wafer: Standard wafers 2″ to 8“

Sides processed: One

Dry Chlorinated Thermal Oxidation:

Thickness: 10 – 300nm

Thickness Tolerance: > 50nm +/- 5%

Film Stress: -320 +/- 50 MPa

Gases: Oxygen

Chemical Vapor: TransLC (Chlorine Source)

Equipment: Horizontal Furnace

Wafer: Standard wafers 2″ to 8“

Sides processed: Both

Silicon Nitrides

The differences between Stoichiometric LPCVD Nitride, Low Stress LPCVD Nitride and Super Low Stress LPCVD Nitride lie in their respective properties and applications. Overall, Stoichiometric LPCVD Nitride, Low Stress LPCVD Nitride and Super Low Stress LPCVD Nitride offer different options for customizing the layer properties according to the requirements of each application.

Stoichiometric LPCVD Nitride

Stoichiometric LPCVD nitride refers to a nitride layer produced during the LPCVD process that has a precisely balanced chemical composition corresponding to ideal stoichiometric ratios. This layer typically has a high density and good thermal stability, making it ideal for applications where precise control of layer properties is required, such as a barrier layer in semiconductor devices.

Low Stress LPCVD Nitride

Low stress LPCVD nitride refers to a nitride layer that is produced during the LPCVD process and is specially designed to exhibit low residual stresses. This layer is well suited for applications in which mechanical stresses in the layer must be reduced in order to avoid deformation or cracks, for example as an insulator layer in MEMS devices or as a passivation layer in integrated circuits.

Super Low Stress LPCVD Nitride

Super Low Stress LPCVD Nitride refers to a nitride layer that is produced during the LPCVD process and has extremely low residual stresses. This layer offers even greater relief from mechanical stresses compared to conventional low stress LPCVD nitride layers and is therefore used in applications where the highest demands are placed on mechanical stability and reliability, such as in high-precision MEMS devices or in optoelectronics.

| Stoichiometric LPCVD Nitride: | Low Stress LPCVD Nitride: | Super Low Stress LPCVD Nitride: | |

|---|---|---|---|

| Thickness: | 10 – 450nm | 10 – 2000nm | 10 – 2000nm |

| Thickness Tolerance: | > 50nm +/- 5% | > 50nm +/- 5% | > 50nm +/- 5% |

| Refractive Index: | 2,0 +/- 0,05 @ 632,8 nm | 2,0 +/- 0,05 @ 632,8 nm | 2,0 +/- 0,05 @ 632,8 nm |

| Film Stress: | 800 +/- 50 MPa | <250 +/- 50 MPa | <100 +/- 50 MPa |

| Temperatur: | ∼800 °C | ∼820 °C | ∼820 °C |

| Gases: | Dichlorosilane, Ammonia | Dichlorosilane, Ammonia | Dichlorosilane, Ammonia |

| Equipment: | Horizontal Furnace | Horizontal Furnace | Horizontal Furnace |

| Wafer: | Standard wafers 2" to 8“ | Standard wafers 2" to 8“ | Standard wafers 2" to 8“ |

| Sides processed: | Both | Both | Both |

| PECVD Nitride: | PECVD Low Stress Nitride: | |

|---|---|---|

| Thickness: | 30 – 500nm | 30 – 200nm |

| Thickness Tolerance: | > 100nm +/- 7% | > 100nm +/- 7% |

| Refractive Index: | 1,98 +/- 0,05 @ 632,8 nm | 1,98 +/- 0,05 @ 632,8 nm |

| Film Stress: | -400 +/- 50 MPa | <100 +/- 50 MPa |

| Temperatur: | 300 °C – 400 °C | 300 °C – 400 °C |

| Gases: | Saline, Ammonia, Nitrous Oxide | Saline, Ammonia, Nitrous Oxide |

| Equipment: | Plasma-enhanced chemical vapour deposition | Plasma-enhanced chemical vapour deposition |

| Wafer: | Standard wafers 2" to 12“ | Standard wafers 2" to 12“ |

| Sides processed: | One | One |

Metals

Please contact us and tell us about your specific requirements and wishes.

We will be happy to advise you on the right specification for your application.

Please call us on +49-(0)8191-478747 or contact us by E-Mail.

E-Beam Evaporation Metal Deposition:

Thickness: 25 – 2000nm

Thickness Tolerance: Target Thickness +/- 10%

Wafer: Standard wafers 4″ to 8“

Sides processed: One

E-Beam Evaporation Metals : Al, Al2O3, Cr, Cu, Au, In,

Mo, Ni, Pt, Sn, Ti, SiO2, Ag

PVD Sputter Metal Deposition:

Thickness: 25 – 2000nm

Thickness Tolerance: Target Thickness +/- 10%

Wafer: Standard wafers 2″ to 12“

Sides processed: One

PVD Sputter Metal Films: Al, AlCu, AlSi, Cu, Ti, Cr, Ta,

TiW, W, Ni, Ta2O5, TaN, TiN